Our Sheroz Earthworks Diaries

Our Sheroz Earthworks Diaries

Blog Article

5 Simple Techniques For Sheroz Earthworks

Table of ContentsSheroz Earthworks Can Be Fun For EveryoneSome Of Sheroz EarthworksSome Ideas on Sheroz Earthworks You Need To KnowThe Sheroz Earthworks PDFsWhat Does Sheroz Earthworks Mean?

For any kind of earthwork specialist, it is vital to do job with high quality, precision, and on schedule. Making use of device control in work makers makes it possible for optimizing the various phases in the earthwork procedure, from preparing to the upkeep phase - topcon laser level. The equipment control system assists the maker driver in achieving the target airplane swiftly and conveniently

The device control system guides the operator with centimeter accuracy. Remote assistance saves time and money, as it decreases downtime in jobsites.

Some Of Sheroz Earthworks

Added training and guidelines are constantly available over remote assistance when needed. The earthmoving industry has actually utilized our field-proven services because the early 1990s. Our system's parts are meticulously designed to stand up to the rough conditions of construction sites. Contrast of the same project implemented utilizing machine control versus the typical approach exposes that, typically, the standard approach needs 50% more time to achieve the same task as the technology-assisted method. https://www.mixcloud.com/sherozau1/.

Enter the Xsite device control system; it's below to provide you with a considerable benefit when functioning with earthmoving machinery. Discover exactly how Xsite Maker Control can boost your efficiency and guarantee job security! Xsite Machine Control systems can be installed to any kind of excavator from mini excavators to large mining excavators.

How does device control job? In 2D systems, the equipment is geared up with calibrated disposition sensors. These sensing units are mounted on the pre-determined parts of the maker in excavators the sensor are usually installed to the structure, boom (or booms), miner arm and to the quick coupler - topcon laser levels. By utilizing the data obtained from these sensors the system can determine the specific position of the excavators container pointer in importance to a reference point.

The system is really easy to find out the essentials can be taught in under one hour of training. Just how does the remote assistance work? A wireless internet link makes it possible to develop a remote link between the device control system and the service.

About Sheroz Earthworks

Xsite Device Control systems support open basic data formats, allowing smooth details flow from one system i was reading this to one more. Depending on your choice of system (with or without placing, i.e., 2D or 3D), your machine is outfitted with disposition sensing units, a controller unit, and a display/operating panel.

Many software and hardware remedies exist to assist figure out a machine's existing position on the planet and contrast it with a desired layout surfaceand construction drivers can do even more to leverage the benefits. Device control is the use of different placing sensors and a screen to provide the driver with a referral in between the position of the bucket or blade and the target grade.

Depending on the configuration, maker control systems can provide the driver with an easy visual overview to pail or blade placement, or can automatically move the blade to quality by speaking to the maker's hydraulics - https://www.reverbnation.com/artist/sherozearthworks. There are equipment control systems available for just about any kind of device: graders, dozers, excavators, soil and asphalt compactors, scrapers, trimmers, milling devices, and pavers

How Sheroz Earthworks can Save You Time, Stress, and Money.

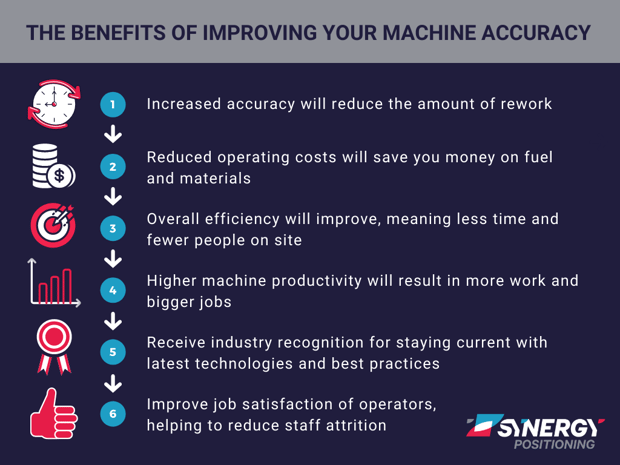

Some benefits include reduced rework, boosted task performance, and reduced checking expenses. Machine control can also aid boost efficiency and lower total expenses. This innovation is transforming the means the building and construction industry works. Construction devices without machine control will end up being a distant memory and the benefits acquired from it will certainly be many.

Trimble device control systems supply a myriad of benefits to any person that uses earthwork equipment and, at EarthCalc, we can offer you with 3D declare your device control-enable tools. Unsure if equipment control deserves the cost? Think about the following reasons why you require to consider this alternative.

Making use of general practitioner aligned with your 3D design data, these systems essentially guarantee that you will certainly get rid of or place the correct amount of material at the building and construction website. On a lot of building sites, revamp is a common and irritating reality, however with Trimble equipment control, you can remove the requirement for rework.

Sheroz Earthworks - An Overview

Usually, with Trimble device control, you can remove excess devices at a certain work website. As an example, a task that might have called for making use of three or four pieces of digging deep into devices currently might need only 2 tools to achieve the exact same job in much less time. This allows you to relocate your equipment to another work site and handle numerous work at one time.

Report this page